I was a guest on an automotive enthusiast podcast called B-Squad Hot Rod! It's a podcast about armatures getting neck deep into automotive culture. We had a fun time talking about winter tires, Miata's, racing with Land O' Lakes Region SCCA, NASA, and IIRA Ice Racing, Minnesota. For being a live interview, I don't think I put my foot too far in my mouth!  For new listeners,to this show, some of the humor is kind of is specific to the podcast; for instance: an orange cone means the topic has been brought way off topic.

For new listeners,to this show, some of the humor is kind of is specific to the podcast; for instance: an orange cone means the topic has been brought way off topic.

Friday, December 20, 2019

Sunday, November 17, 2019

Belly pan/tunnel shield

I purchased the "Aluminum Street Shield Tunnel Brace" from ECS Tuning for my 2018 Golf Alltrack. The biggest reason I purchased it was for aerodynamics. I have no intentions of being hella-low nor doing any real off-roading where the skid plate would scrape and would protect the car. It will add some structure rigidity but I doubt I will notice any difference. The unit is stout! It weighs in at 15lbs!

Installation was pretty straight forward. I love how the kit doesn't require any drilling, welding, or fabrication. A provided special bracket gets installed between the front sub-frame and the exhaust hanger for the front of the plate. The middle of the plate utilizes the bolts for the drive shaft center bearing. The rear portion of the plate is fastened where there is an OEM chassis brace. One does need to trim the OEM heat shield a bit so the shield will sit flush against the bearing bracket, not a big deal.

I ran into clearance issues with the OEM chassis brace at the rear. I was able to pinch the offending OEM brace with a bench vice. The very front of the the brace bolts to the fore mentioned bracket that is sandwiched between the sub-frame and exhaust hanger The holes in the plate need to be ovaled like an extra 1/16th of an inch.

I really want to wrap the exhaust system in thermal wrap or get it ceramic coated. The reason being all the heat in the exhaust system is not in a mostly enclosed chamber and I'd rather not have all that extra heat trapped in the car.

Installation was pretty straight forward. I love how the kit doesn't require any drilling, welding, or fabrication. A provided special bracket gets installed between the front sub-frame and the exhaust hanger for the front of the plate. The middle of the plate utilizes the bolts for the drive shaft center bearing. The rear portion of the plate is fastened where there is an OEM chassis brace. One does need to trim the OEM heat shield a bit so the shield will sit flush against the bearing bracket, not a big deal.

I ran into clearance issues with the OEM chassis brace at the rear. I was able to pinch the offending OEM brace with a bench vice. The very front of the the brace bolts to the fore mentioned bracket that is sandwiched between the sub-frame and exhaust hanger The holes in the plate need to be ovaled like an extra 1/16th of an inch.

I really want to wrap the exhaust system in thermal wrap or get it ceramic coated. The reason being all the heat in the exhaust system is not in a mostly enclosed chamber and I'd rather not have all that extra heat trapped in the car.

From the front of the car looking back.

from the back of the car looking forward.

Another front of car looking back

Friday, November 15, 2019

First of many "buy winter tires" rants!

Every year I post up facts and figures and try to persuade people to buy winter tires. This time, I wrote up a quick and very basic explanation on the differences between Summer, All season, and winter tires.

Pictured from left to right: All Season, Summer, Winter

It is a complete over-simplification but the two biggest factors in tires come down to tread pattern design and rubber compound.

First the Summer tire (middle). It has the largest blocks (less void area (the gaps in the tread)) and no sipping (the paper thin cuts in the tread blocks). This tire is maximized for high speed stability and cornering, the more rubber it has in contact with the road the more traction it has. The larger the blocks of tread the less squirmy the car feels. The tread pattern has kind of a swept back pattern to expel water away from the direction of travel and out. The type of rubber used on this tire is made to stand up to higher temperatures and provide more traction at higher temps. Conversely this rubber compound turns into the equivalent of hockey pucks below 35 degrees which can make things dangerous when cold.

Next the winter tire (right). It has large amount of void area between the blocks of tread, and their is more of them. These work kinda like shovels or paddles to pull one through the snow and slush. Look closely at the tread blocks, take notice of all those very thin cuts. Those are called sipping. They allow the tread block to flex, bend, and be more pliable on cold, snowy, and icy surfaces. The rubber compound is specifically designed to remain very soft in cold temperatures. Conversely, in the hot summer months the tire is way beyond it's design, wears really quickly and feel like driving on marshmallows.

Lastly, the All-Season tire, or as I call it, the no-season tire. It is a compromise between summer and winter. It has some sipping in the tread blocks. There is balance between tread blocks and void area. The compound tries it's best to work in both the cold and hot, but falls short. It is a tire that works great at nothing, but does "ok" at everything. It is the Swiss army knife of tires. A Swiss Army knife t isn't very good as a screw driver, nor is it very good at cutting a nice juicy steak; but it does do the job.

So does one need multiple sets of tires? I don't know, does one need 6 pairs of shoes? I mean you don't wear the same pair of sneakers though the snow, to a wedding, and to play sports ball do you?

Good 3.5 minute video from TireRack https://www.tirerack.com/videos/index.jsp?video=593

Sunday, November 10, 2019

Friday, November 8, 2019

Crankcase catch cans

Not directly racing related but good to know if you have a direct injection motor or are running crank case catch can. This article assumes knowledge of how internal combustion motors operate.

Direct Injection (DI) motors are great, they make more power while using less fuel. How? The fuel injector is located in the cylinder head and spray fuel directly into the combustion chamber allowing for a more precise and atomized application of fuel. In Mulit-Port Injection (MPI) systems the fuel injector is located in the intake manifold behind the intake valve. Both air coming into the motor and fuel both must flow into the cylinder head around the intake valve.

Now the problem. DI motors have a horrible habit of having the intake valve getting caked up with nasty carbon deposits, which leads to lower performance because less air can get in, and in some case the valve won't fully close. Why? Well motors have a PCV (Positive Crankcase Valve) system, where hot oily vapors from the crank case are sucked back up into the air intake where it can be burnt. It is much friendlier for the environment to burn this oily vapor vs. just expelling it to the atmosphere. So MPI motors have the injector spraying fuel directly at the intake valves, it basically washes off the intake valves. Since the fuel injector for DI motors is located in the cylinder head, there is nothing to clean off the intake valves. Thus over time (as low as 40,000) miles the the intake valves become all caked up with black carbon. Worse than an old man who eats bacon and hamburgers every day!

Two things can help make this issue better. First one is running a quality oil that is made for direct injection motors. What makes an oil better for DI motors? The oil has less tendency to evaporate. Less evaporation means less oil to be sucked into the intake system, thus carbon build up. Second is install a catch can with baffling. The catch can goes inline with the tube carries the crank case vapors to the air intake. The purpose of the catch can is to get those oil vapors to turn into oil droplets, and those oil droplets collect in the bottom of the catch can, so the air the motor is ingesting has less oil to form carbon deposits.

Ok great problem solved! Right? Well, unless you live in an area were it gets real cold. That oily vapor coming out of the crank case into the catch can then into the intake system, it contains a lot of moisture. That moisture can freeze and restrict the flow out of the crank case. Worst possible scenario now, is that crank case pressure gets to high, and the vapor finds the next easiest place to escape, which often time is the crank shaft main seal. If the crankshaft main seal goes, the whole transmission and clutch/flywheel need to come out! Some people remove their crank case catch can during the winter and return to the stock setup to avoid that issue, but now the problem of carbon build up returns.

My solution! I purchased a catch can made specifically for my car, that has really short hoses. Some kits have multiple feet of hose which is just more area for the lines to get frozen and clogged. Next, I remembered that the Volkswagen MK3 GTI VR6 has these little heating elements in the crank case lines. I was able to find two of them in my parts pile, with the harnesses, I wired them up to be on with ignition. Now both crank case vapor going into and out of the catch can must pass through the heating element.

Direct Injection (DI) motors are great, they make more power while using less fuel. How? The fuel injector is located in the cylinder head and spray fuel directly into the combustion chamber allowing for a more precise and atomized application of fuel. In Mulit-Port Injection (MPI) systems the fuel injector is located in the intake manifold behind the intake valve. Both air coming into the motor and fuel both must flow into the cylinder head around the intake valve.

Now the problem. DI motors have a horrible habit of having the intake valve getting caked up with nasty carbon deposits, which leads to lower performance because less air can get in, and in some case the valve won't fully close. Why? Well motors have a PCV (Positive Crankcase Valve) system, where hot oily vapors from the crank case are sucked back up into the air intake where it can be burnt. It is much friendlier for the environment to burn this oily vapor vs. just expelling it to the atmosphere. So MPI motors have the injector spraying fuel directly at the intake valves, it basically washes off the intake valves. Since the fuel injector for DI motors is located in the cylinder head, there is nothing to clean off the intake valves. Thus over time (as low as 40,000) miles the the intake valves become all caked up with black carbon. Worse than an old man who eats bacon and hamburgers every day!

Two things can help make this issue better. First one is running a quality oil that is made for direct injection motors. What makes an oil better for DI motors? The oil has less tendency to evaporate. Less evaporation means less oil to be sucked into the intake system, thus carbon build up. Second is install a catch can with baffling. The catch can goes inline with the tube carries the crank case vapors to the air intake. The purpose of the catch can is to get those oil vapors to turn into oil droplets, and those oil droplets collect in the bottom of the catch can, so the air the motor is ingesting has less oil to form carbon deposits.

Ok great problem solved! Right? Well, unless you live in an area were it gets real cold. That oily vapor coming out of the crank case into the catch can then into the intake system, it contains a lot of moisture. That moisture can freeze and restrict the flow out of the crank case. Worst possible scenario now, is that crank case pressure gets to high, and the vapor finds the next easiest place to escape, which often time is the crank shaft main seal. If the crankshaft main seal goes, the whole transmission and clutch/flywheel need to come out! Some people remove their crank case catch can during the winter and return to the stock setup to avoid that issue, but now the problem of carbon build up returns.

My solution! I purchased a catch can made specifically for my car, that has really short hoses. Some kits have multiple feet of hose which is just more area for the lines to get frozen and clogged. Next, I remembered that the Volkswagen MK3 GTI VR6 has these little heating elements in the crank case lines. I was able to find two of them in my parts pile, with the harnesses, I wired them up to be on with ignition. Now both crank case vapor going into and out of the catch can must pass through the heating element.

Tuesday, October 22, 2019

World Racing League at Hallett Raceway 10/19 & 10/20/2019

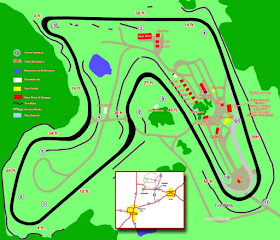

Hallett Raceway is a 1.8 mile long race track located in Jennings Oklahoma. It is one of the very few tracks that can be run both clock wise and counter clockwise. With World Racing League we ran CCW on Saturday and CW on Sunday.

On Saturday 45 cars started, 9 cars in GP4 with us in the Gensoku 1995 Mazda Miata. Our car was able to put down the same lap times as the 1st place car but were only able to get 2nd place in class, 20th over all, completing 199 laps in 8 hours. Sunday we also got 2nd place completing 211 laps in 8 hours, 17th over all.

Amazingly we had zero mechanical issues for the entire 16 hours of racing! We had one small car to car contact which did have a minor affect on rear toe.

Photo credit to Jim Rowland.

Tuesday, October 1, 2019

Historic Motorsports Racing @ Road Atlanta and MaxSpeed Track Days 9/29/19

I was in Atlanta for work and had a day off. So I made the trek over to Road Atlanta to spectate some vintage auto racing with Historic MotorSports Racing.

I got meetup with the fine folks at MaxSpeed Track Days and Maxspeed GarageClub. Which happens to be just down the road from the track. The garage club is really interesting concept; I wish I was closer! Basically for $100 monthly rate, one gets 24*7 access garage, tools, lift, with an air conditioned lounge with internet access.

Friday, September 13, 2019

Hennepin Restomods Open House

Not directly racing related, but close enough; see the part about the RX7. The shop owner has also competed in some Chump Car races, so there is my justification! I love old cars, I love them even more when they can start, stop more like modern cars. A lot of people are nay-sayers when it comes to retro-mods (a classic car with some modern components swapped in). I get it, somethings should be kept original for better or worse for the sake of being historically accurate. However, once one drives a car with leaf springs and drum brakes on all four corners, requires a rain dance of pulling the choke cable, pumping the gas pedal 4 times (not three, not six) to get the thing to start, or the fact it can't do the legal posted highway speed limit, the novelty of a classic wears off.

Hennepin Restomods had an open house so I swung in to see what projects where in the shop.

This Cheverolet is going to be a mobile bar.

Originally a Dodge van with an ABC (Aluminum Bodies Company) shell; now sitting on shortened '02 Silverado 35000 chassis with a 6.0l LS LQ4 power plant. It's new life will be a food truck.

Dodge

The original frame for the Dodge. Independent rear end?!?

Body on frame swap

GrassRoots MotorSports Challenge 2004 contender and 2005 winner. Mazda RX7 w/ a Ford 302 swap.

Extended cab Ford?

LS Swap

I am a big fan of these retro-fit fuel injection systems. Restomods is a FiTech installer.

Trabant